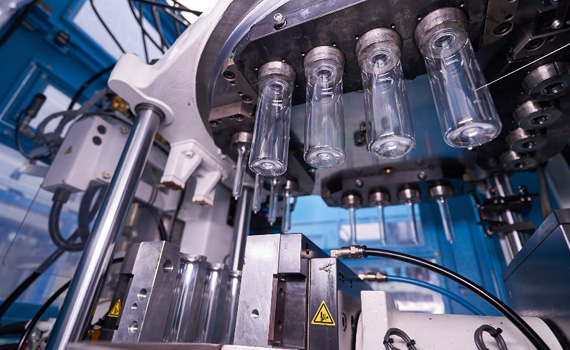

The company owns fully automatic bottle blow moulding machines to produce HDPE and PP packaging. The extrusion blowmoulding method allows for bottles, jars, cans and ampoules (up to 200 ml) to be manufactured.

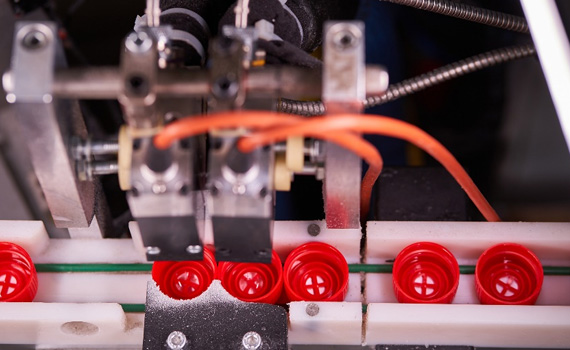

The company is also equipped with modern ARBURG machines enabling the injection method production of PP, LDPE or HDPE nuts, caps, plugs, bottletop dispensers, wax applicator spatulas, toilet bar containers, measuring scoops and more.

Since recently in the company’s procession there has been 3 new PET bottle blow moulding machines (up to 1000 ml capacity).

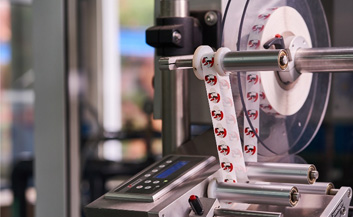

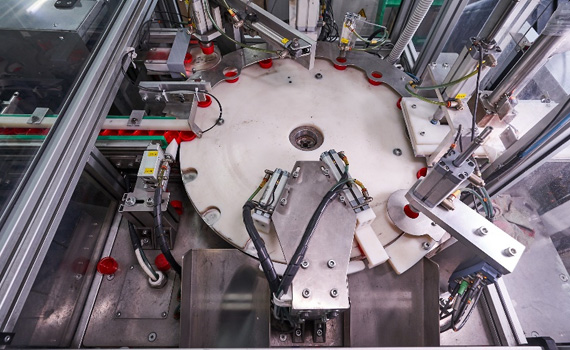

The company owns also modern folding machines and manufactures:

- Flip tops,

- Caps with foam seal liners,

- Caps with foil seal liner,

- Caps with wax seal liners,

- Caps with vent membranes,

- Plastic sponge applicators.

By investing in energy-efficient machines we have been able to decrease the costs of the production and continue manufacturing the highest quality of products at competitive prices.